Nickel Applications

The following are some of the applications for nickel-metal:

- It is mostly used as an alloying element in corrosion-resistant stainless steel, alloy steels, non-ferrous metals, and other alloys;

- Nickel coatings can be deposited electrolytically through electroplating, chemically through electroless deposition, or autocatalytically through autocatalytic deposition;

- Tubing for desalination plants;

- Additives in amour plate and burglarproof vaults metals;

- To make a green color in glass products;

- As a hydrogenation catalyst for vegetable oils;

- Ceramic manufacturing;

- Alnico magnets;

- Nickel-cadmium and nickel-metal hydride-based storage batteries. These rechargeable batteries are utilized in the electric vehicle sector, mobile phones, personal entertainment equipment, and other applications;

- Electronic and aerospace applications, chemical, and food processing equipment, anodes and cathodes, caustics evaporators, and heat shields all employ high purity nickels;

- Aircraft turbines components;

- Spring, switches, bellows, diaphragms, and tiny valves are all made of beryllium nickel;

- Thermometer bulbs and resistance thermometers;

- Glass to metal and ceramic to metal seals;

- Marine, petroleum, and chemical processing equipment;

- Incineration systems;

- Controlled expansion nickel super-alloys;

- Paramagnetic and shape memory alloys are utilized in fire sprinkler actuators, tap water anti-scalding devices, green home window hinges, flow regulators, spacecraft solar-panel releases, a variety of toys, and novelties, and underwire brassieres;

- A metal that may be found in everything from the batteries that power our television remotes to stainless steel, which is used to make buildings and cars, and is a fixture of our daily life;

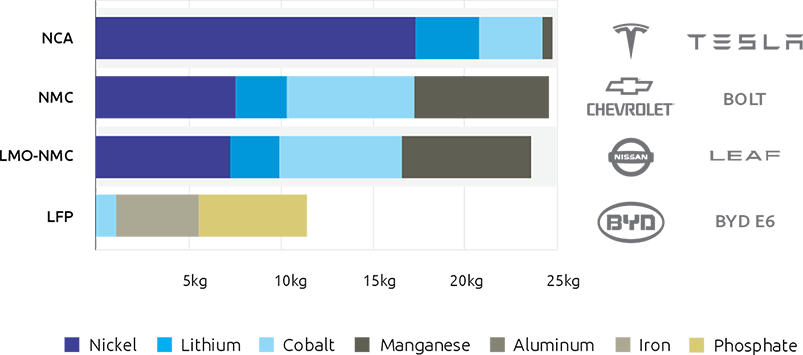

- Although most nickel is used in stainless steel, it is becoming more popular in the electric vehicle (EV) industry, which is about to hit a tipping point in the penetration curve in the coming years. In the lithium-ion battery cathodes used by EV manufacturers, nickel is the most important metal by mass. Nickel accounts for one-third of Nickel Manganese Cobalt (NMC) cathodes and 80% of Nickel Cobalt Aluminum (NCA) cathodes at the moment.

Nickel Applications Explained

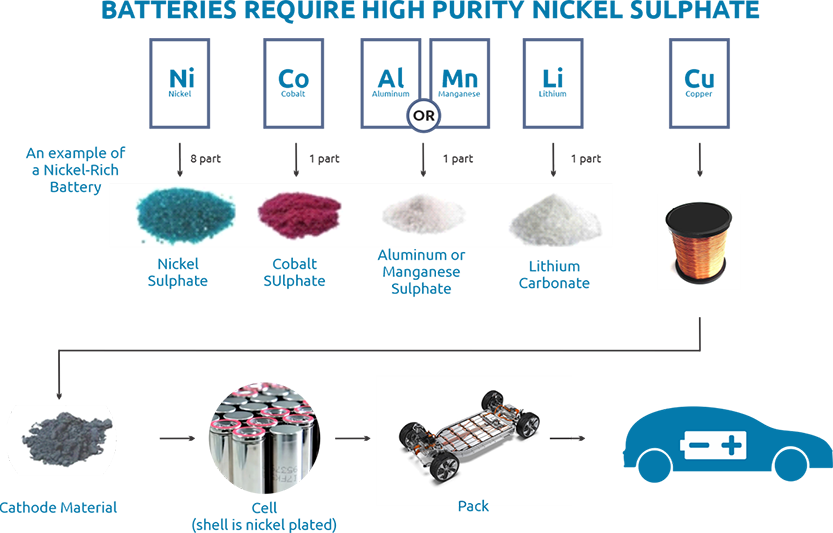

As the amount of nickel in the battery cathode increases, electric vehicles may drive long distances. EV makers demand batteries with a higher energy density, more power, and a longer lifetime, all while remaining safe and affordable.

Due to rising lithium and cobalt prices, battery and electric vehicle makers are looking to change their present material composition by reducing cobalt and increasing nickel to improve performance and lower costs. Automakers recognize that lower production costs will lead to greater acceptance of electric vehicles and a shift toward profitability.

Nickel, which is largely used to make stainless steel, is already one of the world's most important metal markets, with a market value of more than $20 billion. The nickel market's future influence will be determined by battery demand and EV market expansion.

According to the World Health Organization, air pollution is the world's most serious environmental health threat, and the transportation industry is one of the biggest emitters of CO2. Governments have begun to respond by prohibiting the long-term sale of gasoline and diesel automobiles in different areas.

EVs presently account for around 1% of vehicle demand, resulting in 70,000 tonnes of nickel demand, or about 3% of the overall market. Nickel demand is steadily increasing as EV popularity rises.

According to the World Health Organization, air pollution is the world's most serious environmental health threat, and the transportation industry is one of the biggest emitters of CO2. Governments have begun to respond by prohibiting the long-term sale of gasoline and diesel automobiles in different areas.

EVs presently account for around 1% of vehicle demand, resulting in 70,000 tonnes of nickel demand, or about 3% of the overall market. Nickel demand is steadily increasing as EV popularity rises.

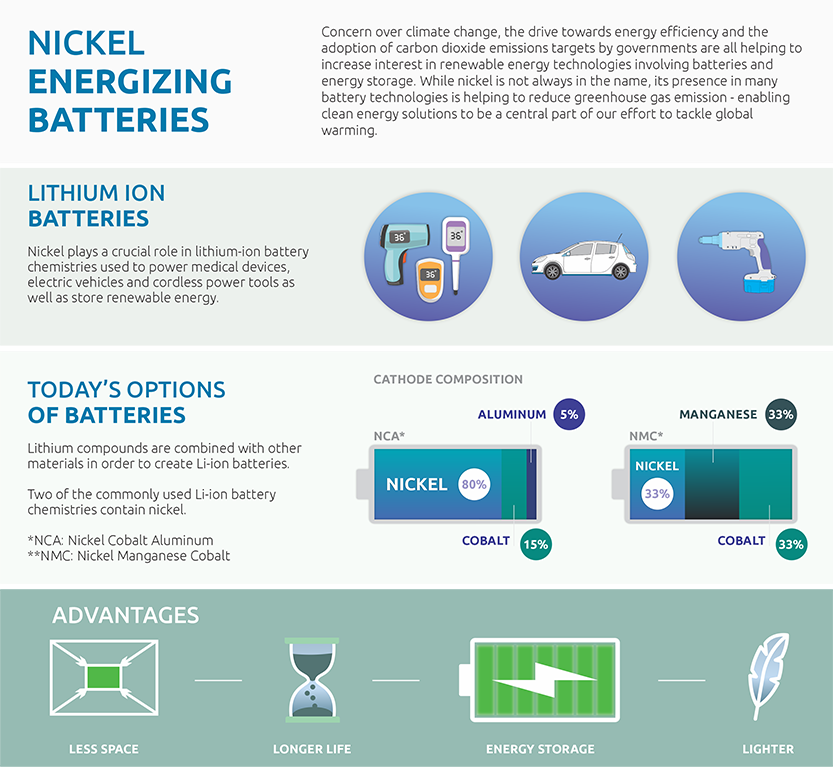

Nickel plays a critical role in lithium-ion (Li-ion) batteries, which are powering much of the electric vehicle revolution.

Nickel (Ni) has been widely used in batteries for a long time, most notably in nickel-cadmium (NiCd) and the longer-lasting nickel-metal hydride (NiMH) rechargeable batteries, which became popular in the 1980s. Their use in power tools and early digital cameras demonstrated the possibility of portable technologies, transforming how we work and live. In the mid-1990s, the Toyota Prius was the first automobile to use NiMH batteries in a substantial way. Around the same time, the first commercial Li-ion battery applications appeared, first in camcorders and then in smartphones, laptops, and a slew of other portable gadgets that we now take for granted.

The primary benefit of nickel in batteries is that it allows for increased energy density and storage capacity at a lower cost. Further advancements in nickel-containing battery technology indicate that it will play a larger role in energy storage systems, lowering the cost per kWh of battery storage. It makes the use of intermittent renewable energy sources like wind and solar to replace fossil fuels more viable.

“NICKEL IN BATTERIES HELPS DELIVER HIGHER ENERGY DENSITY AND GREATER STORAGE CAPACITY AT A LOWER COST”

Batteries for Electric Vehicles

Along with this growing market share, battery technology is improving, which is another reason why the use of nickel-containing Li-ion batteries is expected to increase. Nickel Cobalt Aluminium (NCA) and Nickel Manganese Cobalt (NMC), two of the most widely used types of batteries, contain 80 % and 33 % nickel, respectively; newer NMC formulations are also reaching 80 % nickel. Nickel is now used in the majority of Li-ion batteries.

As the increased power density of Li-ion batteries became crucial for driving vehicles over long distances, they were included in the next generation of electric cars. Although electric cars make up a small percentage of the worldwide automobile fleet, their market share is growing rapidly and is expected to continue to do so in the future years. According to some estimates, they will account for more than 10% of vehicles by 2025, with the majority of them being powered by nickel-containing Li-ion batteries. Nickel in car batteries provides higher energy density and storage at a lower cost, allowing vehicles to travel further distances, which is currently one of the barriers to EV adoption.

“NICKEL IN CAR BATTERIES: DELIVERING A LONGER RANGE FOR VEHICLES”

The Importance of Nickel in Rechargeable Battery Technologies

An electric battery is made up of one or more electrochemical cells, each of which has two electrodes (anode and cathode) as well as an electrolyte. Electrons can move from one electrode to the other when they are connected by a route that conducts electricity. When a battery is used to provide electric power, the anode produces electrons, which flow and deliver energy when linked to an external device via a circuit.

Batteries are divided into two categories. Primary batteries are one-time-use only; secondary batteries can be recharged and utilized multiple times. Secondary batteries include the lead-acid battery found in automobiles, NiCd (Nickel Cadmium), NiMH (Nickel Metal Hydride), and Li-ion (Lithium-ion) batteries. Nickel is used in the cathodes of many secondary battery designs, including Li-ion batteries.

Batteries for Storage

Energy storage systems based on renewable energy sources are also benefiting from new nickel-containing battery technologies. When the wind or the sun are available, wind turbines or solar panels generate electricity; contemporary battery technology allows this energy to be stored and used as needed.

“MODERN BATTERY TECHNOLOGY ALLOWS ENERGY TO BE STORED FOR USE AS AND WHEN REQUIRED”

A huge increase in renewable energy resources, especially wind and solar, has sped up the adoption of energy storage devices. Batteries are being used to store energy and release it as needed, assisting in the stabilization of our complicated and broad electricity grid.

Li-ion is becoming the dominating technology due to economies of scale. This is due to both Li-lengthy ion's history in the consumer electronics sector and the massive recent investments in Li-ion manufacturing, much of it devoted to the electric vehicle industry. The production capacity of nickel-manganese-cobalt (NMC), which has a typical ratio of 33 % for each element, is being increased by global Li-ion battery cathode material providers.

Recycling Batteries

With the use of nickel-containing Li-ion batteries expected to skyrocket, end-of-life collection and recycling capacity are expected to keep pace. The demand for proven recycling methods will grow as regulations on end-of-life responsibilities, as well as the safe handling and transport of Li-ion batteries, become more stringent. While such processes already exist and may be scaled up to meet demand, forward-thinking businesses throughout the world are looking for efficient and cost-effective ways to meet any potential rise in demand.

Because of toxicity and safety concerns, efficient Li-ion battery recycling is critical for the environment. Batteries must be handled and transported properly. Aside from the environmental benefits, the valuable metals and compounds that may be recovered are a major economic motivation for Li-ion battery recycling. This, of course, includes nickel, which can be found in cathodes and anodes for new batteries. The battery recycling process, which is also known as battery resource recovery, can be pyrometallurgical, hydrometallurgical, or a combination of the two.

The Li-ion worldwide battery market will grow fast as its application in the automobile industry becomes more prevalent. End-of-life recycling will become a major business in the not-too-distant future, with automobile batteries currently having warranties of five to eight years. In the medium term, the increasing amount of batteries accessible for recycling will reward investment in new recycling facilities and technological research that will improve material recovery efficiency and lower costs, contributing to a circular economy.